Quick-Shifting into a New Era of Classic Gearbox Repair and Restoration

The motorcar has taken a battering over the past decade. Widely vilified, perhaps not without merit, for melting the polar icecaps and Tsunami-ing Pacific coastlines. At times, it feels as though the car has become the necessary evil of the modern age. Add to that, ongoing increases in fuel prices and road taxes, and widening of emissions exclusion zones (in London specifically), and it seems evident that the authorities would rather the car be removed from our lives all together.

Even the all-conquering, flavour-of-the-month, planet-saving electric car is, according to some political leaders, in line for additional mileage taxation. Yes, you read that correctly. Governments are already discussing ways to tax electric car owners – potentially on a mileage-driven basis, as opposed to engine size (CO2 output) – to ensure they continue to rake in their pound of flesh from those of us who choose private transport over public. In today’s mobility landscape, the personally-owned and operated motor vehicle is, it seems, a liability.

It’s easy to forget, therefore, how special they actually are. And how vital it is that the classics are preserved.

Put aside the independence, the empowerment, and the freedom of movement they offer. From a technical point of view alone, the motorcar – and the people who design and build them – has played a leading role in mechanical innovation and engineering progress for well over a hundred years. Manufacturing processes, outside of the automotive sector, are more efficient because of the car. The electronics industry owes much of its momentum to the motorcar. If we began to list the hundreds of virtually indispensable products derived from petrochemical processes, this article would be as long, and as mentally challenging, as Tolstoy’s Anna Karenina.

The amalgamation of raw mechanical mastery, electronic genius, ergonomic prudence and oftentimes truly inspired design has produced a product that has both mobilised and invigorated nations, and empowered and energised us as individuals in equal measure.

And few parts of the passenger car are more impressive, from an engineering point of view, than the gearbox. While the engine produces power, those many splendid “horses” would be useless without a practical, efficient and reliable way of transmitting that energy to the wheels.

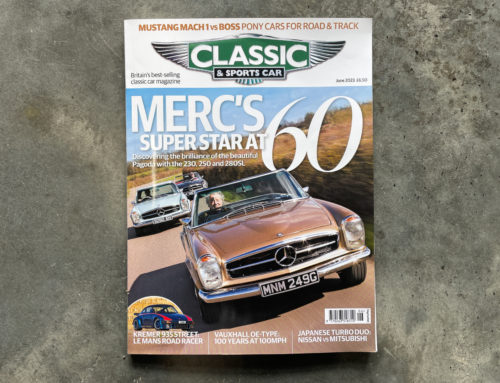

It’s no secret that Mercedes-Benz has been the tip of the engineering sword, quite literally, since the world’s first motorcar rolled out of Carl Benz’s workshop more than 130 years ago. A massive percentage of practically every major technical development has originated from a Mercedes-Benz drawing board. The progress of the gearbox is no different. Mercedes-Benz has built, in-house, some of the finest manual and automatic boxes of this or any era. They are renowned for their smooth, simplistic and solid feel, and for their almost bombproof reliability.

Almost. No mechanical device, regardless of how well-built, lasts forever. And all machines require proper maintenance. For those of us lucky enough to drive a new Merc, one potentially still under warranty, any problem is easily remedied, often without cost, at your local dealer.

If, however, the newer cars don’t ring your bell and it’s a classic you have parked in your garage, repair centres are getting harder to find. Qualified, capable classic Mercedes-Benz service centres are an even rarer bird. Drilling down on specific engineering capabilities, like gearbox expertise, narrows your Google search results even further. The reality is that that generation of technician – the anorak artisan – is being replaced, in most service centres, by a younger breed of mechanic. And while the barriers to entry, especially in a Mercedes-Benz workshop are still challenging, the technology in today’s cars asks different questions. Fewer and fewer younger mechanics are inheriting the experience and skills needed to maintain the previous generation of car.

Enter Paul Smith. Paul cut his teeth – pun intended – on the previous, non-electronic generation of Mercedes-Benz gearboxes. Paul served his apprenticeship in a Mercedes main dealer and paid his dues with a journeyman who’d learnt the trade on Seventies cars. Paul might not be what one would call a workshop dinosaur, but he is proudly from the generation of technicians who still know how to diagnose through decades of experience and gut feel. And, if possible, to repair rather than replace.

“The gearbox is, in my view, the best part of the car,” says Paul. “What we do here, at SLSHOP, is work which is getting more and more difficult to find. The standards we set and the processes we follow are often more stringent than I remember at main dealer level. Management here at SLSHOP are passionate about our workshop being able to offer repairs and servicing at unparalleled standards.” SLSHOP has identified a void in the market. These services, at this level of competence, are almost impossible to find here in the U.K., or abroad.

In talking to Paul about some of the common problems he sees with W113 (the Pagoda), the R107 (the Hart to Hart SL) and the R129 (the Princess Diana SL), Smith laughs and says, “Not that many, if I’m honest. Most of what we see could easily be prevented by scheduled maintenance. Some of it is abuse, but on the whole, these boxes are fantastic. I’ve been diagnosing, removing, and repairing these things since the late ‘90s. If looked after properly, they will last an incredibly long time.”

One common issue with the W113 – if the auto box is battling to shift gears – is a faulty ‘double-stroke’ solenoid. A problem easily remedied with factory spec replacement parts. “We check the pressures. We need 0.7 bar at idle and 2.9 at higher engine speeds. If neither 0.7 or 2.9 bar show, the solenoid is likely stuck requiring a visual inspection. At 0.7 the gearbox will slip, while 2.7 bar generally means no movement. We change the solenoid, and we’re good to go. These K4C 025 units are truly exceptionally reliable. Most of the issues are around age and lack of maintenance.” If your W113 is 1969 or older, chances are the box in your car is designated K4A 025.

On the subject of parts availability, the age of the car can sometimes dictate the wait times, but SLSHOP stock a huge percentage of the necessary parts. A list of factory-approved, independent manufacturing companies – most of which are based in Germany – will build any parts which might potentially be out of stock. Again, the specs of the parts used by SLSHOP are exacting. Only factory-approved will do.

The W113’s automatic boxes utilised fluid coupling, and not torque converter technology. The main difference is the latter makes use of a stator, placed between the impellor and the turbine, helping to multiply the torque and providing more efficient open road cruising. The tolerances and precision of Mercedes’ fluid coupling design, however, even back in the ‘60s, made for a super-smooth gearbox. At the time, it was unparalleled in terms of refinement and reliability. With SLSHOP focusing heavily (but not entirely) on the SLs in the Mercedes Benz range, Paul and the team in the workshop are best placed, and best qualified, to help keep these gems in perfect working order.

The Pagoda came standard with either a 4-speed manual or 4-speed auto, with a rarely optioned 5-speed manual ZF box on special order. One such unicorn was recently sourced and sold through the business. To add depth to today’s choices, SLSHOP now proudly offers a 6-speed manual conversion. The word ‘conversion’ is, in fact, a misleading description. What SLSHOP will do, is replace your existing box with a bespoke Getrag 6-speed unit. This gearbox can be fitted to either your Pagoda or your R107 SL.

Another pain point Paul and the technical team at SLSHOP deal with is being sent the gearbox removed from the vehicle. “Ideally, we want the gearbox while it’s still in the car,” he explains. “There are often issues with fitment and with the external control element. For example: poorly adjusted cables or modulating pressure or vacuum faults which are obviously only evident if the car is still in one piece.”

The R107s, built from 1971 – 1989 saw the introduction of the famed 722 series of automatic boxes. While the European spec list offered a 5-speed manual, the US only offered the auto. Unsurprisingly, irrespective of which side of the pond one studies, it’s the self-shifter that proved the most popular.

“We see some oil starvation issues and basic seal failure – all to be expected with age. A common modification is fitting a nylon bush (to replace an alloy one) in the B2 piston. Wear and tear of the alloy bush will damage the piston. The nylon unit is a fantastic fix, but if the piston is scored, that needs replacing too,” explains Paul. Like many classic car technical experts, Paul encourages people to drive their cars. If the car stands for prolonged periods of time, the paper seals and gaskets will become misshaped and result in pressure issues in the transmission.

- Azurite Blue SL500 for sale at SLSHOP

So good was the design of the 722 gearboxes, that the R129 SLs featured the 722 in modified form, beginning with the designation 722.4. Built from 1989 – 2001, the R129 SL was widely regarded as an engineering masterpiece with a plethora of automotive firsts. A 5-speed manual was available for the 6-cylinder models, but the V8s and V12s all had the automatic fitted. Even as the engines, the electronics, the materials, and the exterior and interior design were all making huge strides forward with the R129, the 722 gearboxes effortlessly kept pace. As the range progressed, so the upgrades to the box rolled on. 722.4 – a 4-speed. 722.5 – a 5-speed.

722.6 was the first major step forward for the unit with the introduction of electronics. Gone was the all-mechanical, analogue system of check-ball and spool valves, and control cables. A digital brain, throwing ones and zeros hither and thither, now replaced vacuum pressures and magnetically actuated solenoids that was fitted in the 722.5.

On the older units, a control cable, not unlike an accelerator cable, joins the throttle – on the carburettor or fuel injection system – to the gearbox’s valve chest. It acts as a position sensor, allowing the gearbox to ‘understand’ what the throttle position is and therefore the engine load. An override system is also fitted – a switch beneath the accelerator pedal that is connected to a solenoid in the valve chest. When you mash the throttle to the floor at lower speeds, the switch tells the solenoid to ‘kickdown’ to first gear. At higher road speeds – usually above 50mph – that kickdown system is bypassed and the valve chest, when asked for more performance, will select the next appropriate gear. 722.6 replaced all of this with circuit boards and electrically controlled solenoids. Paul suggests that kickdown is used sparingly to avoid wearing out the transmission.

In quizzing Paul about the any teething problems initially associated with the digi-brain, or any which have since reared a head, Paul says, “Electronically, you might see RPM sensor failure. Leaking electrical plugs are also common issues. The former will cause the car to go into limp mode, it won’t change beyond 2nd gear. Turning the ignition off and on again will reset this but the problem will resurface.” It goes without saying that any of these sorts of issues are easily dealt with by Paul and the team at SLSHOP.

In closing Paul proudly says, “I’m pedantic. I’m a stickler for doing the job right. And I’ve been doing this long enough to know when that gearbox is working the way it did the day it left the showroom, and when it isn’t. I’m also proud to say that we have an apprenticeship programme here at SLSHOP. Young Matthew is learning fast and quickly becoming a highly skilled technician in his own right. As it was done for me, I’m now passing on what I know.”

READ ABOUT OUR MANUAL CONVERSIONS

SLSHOP don’t restore, repair and sell SLs so that they can sit in a garage. They actively encourage the owners of these magnificent vehicles to drive them. The gearbox – one that is working as the designers intended it to – is an indispensable part of the driving experience. It is for this reason that SLSHOP is investing in these significant resources.

Paul also insists that SL owners understand that gearboxes, just like engines, need servicing. On the Pagoda, every 30 000 miles is your number. On the 722 series (R107 and R129), you’re looking at booking the car in every 36 000 miles. On the very latest Mercedes-Benz gearboxes (the 722.7 onwards), the service intervals are 72,000 miles.

SLSHOP is passionate about keeping these beautiful cars on the road for as long as possible. Sustainability, in the most contemporary understanding of the term, is a cornerstone of their operation. With technicians like Paul fixing rather than replacing, there’s far less ‘junk’ being sent to landfill. SLSHOP will warranty its gearbox rebuilds for 12 months. Follow Paul’s advice on the service intervals, and you’ll almost certainly never need to worry about the warranty.

If you’d like Paul and his team to get your gears shifting better than new, then why not book your Mercedes in today for a health check and honest chat about your options and our services.

SLSHOP Workshops

Share With Your Fellow Enthusiasts

Quick-Shifting into a New Era of Classic Gearbox Repair and Restoration

The motorcar has taken a battering over the past decade. Widely vilified, perhaps not without merit, for melting the polar icecaps and Tsunami-ing Pacific coastlines. At times, it feels as though the car has become the necessary evil of the modern age. Add to that, ongoing increases in fuel prices and road taxes, and widening of emissions exclusion zones (in London specifically), and it seems evident that the authorities would rather the car be removed from our lives all together.

Even the all-conquering, flavour-of-the-month, planet-saving electric car is, according to some political leaders, in line for additional mileage taxation. Yes, you read that correctly. Governments are already discussing ways to tax electric car owners – potentially on a mileage-driven basis, as opposed to engine size (CO2 output) – to ensure they continue to rake in their pound of flesh from those of us who choose private transport over public. In today’s mobility landscape, the personally-owned and operated motor vehicle is, it seems, a liability.

It’s easy to forget, therefore, how special they actually are. And how vital it is that the classics are preserved.

Put aside the independence, the empowerment, and the freedom of movement they offer. From a technical point of view alone, the motorcar – and the people who design and build them – has played a leading role in mechanical innovation and engineering progress for well over a hundred years. Manufacturing processes, outside of the automotive sector, are more efficient because of the car. The electronics industry owes much of its momentum to the motorcar. If we began to list the hundreds of virtually indispensable products derived from petrochemical processes, this article would be as long, and as mentally challenging, as Tolstoy’s Anna Karenina.

The amalgamation of raw mechanical mastery, electronic genius, ergonomic prudence and oftentimes truly inspired design has produced a product that has both mobilised and invigorated nations, and empowered and energised us as individuals in equal measure.

And few parts of the passenger car are more impressive, from an engineering point of view, than the gearbox. While the engine produces power, those many splendid “horses” would be useless without a practical, efficient and reliable way of transmitting that energy to the wheels.

It’s no secret that Mercedes-Benz has been the tip of the engineering sword, quite literally, since the world’s first motorcar rolled out of Carl Benz’s workshop more than 130 years ago. A massive percentage of practically every major technical development has originated from a Mercedes-Benz drawing board. The progress of the gearbox is no different. Mercedes-Benz has built, in-house, some of the finest manual and automatic boxes of this or any era. They are renowned for their smooth, simplistic and solid feel, and for their almost bombproof reliability.

Almost. No mechanical device, regardless of how well-built, lasts forever. And all machines require proper maintenance. For those of us lucky enough to drive a new Merc, one potentially still under warranty, any problem is easily remedied, often without cost, at your local dealer.

If, however, the newer cars don’t ring your bell and it’s a classic you have parked in your garage, repair centres are getting harder to find. Qualified, capable classic Mercedes-Benz service centres are an even rarer bird. Drilling down on specific engineering capabilities, like gearbox expertise, narrows your Google search results even further. The reality is that that generation of technician – the anorak artisan – is being replaced, in most service centres, by a younger breed of mechanic. And while the barriers to entry, especially in a Mercedes-Benz workshop are still challenging, the technology in today’s cars asks different questions. Fewer and fewer younger mechanics are inheriting the experience and skills needed to maintain the previous generation of car.

Enter Paul Smith. Paul cut his teeth – pun intended – on the previous, non-electronic generation of Mercedes-Benz gearboxes. Paul served his apprenticeship in a Mercedes main dealer and paid his dues with a journeyman who’d learnt the trade on Seventies cars. Paul might not be what one would call a workshop dinosaur, but he is proudly from the generation of technicians who still know how to diagnose through decades of experience and gut feel. And, if possible, to repair rather than replace.

“The gearbox is, in my view, the best part of the car,” says Paul. “What we do here, at SLSHOP, is work which is getting more and more difficult to find. The standards we set and the processes we follow are often more stringent than I remember at main dealer level. Management here at SLSHOP are passionate about our workshop being able to offer repairs and servicing at unparalleled standards.” SLSHOP has identified a void in the market. These services, at this level of competence, are almost impossible to find here in the U.K., or abroad.

In talking to Paul about some of the common problems he sees with W113 (the Pagoda), the R107 (the Hart to Hart SL) and the R129 (the Princess Diana SL), Smith laughs and says, “Not that many, if I’m honest. Most of what we see could easily be prevented by scheduled maintenance. Some of it is abuse, but on the whole, these boxes are fantastic. I’ve been diagnosing, removing, and repairing these things since the late ‘90s. If looked after properly, they will last an incredibly long time.”

One common issue with the W113 – if the auto box is battling to shift gears – is a faulty ‘double-stroke’ solenoid. A problem easily remedied with factory spec replacement parts. “We check the pressures. We need 0.7 bar at idle and 2.9 at higher engine speeds. If neither 0.7 or 2.9 bar show, the solenoid is likely stuck requiring a visual inspection. At 0.7 the gearbox will slip, while 2.7 bar generally means no movement. We change the solenoid, and we’re good to go. These K4C 025 units are truly exceptionally reliable. Most of the issues are around age and lack of maintenance.” If your W113 is 1969 or older, chances are the box in your car is designated K4A 025.

On the subject of parts availability, the age of the car can sometimes dictate the wait times, but SLSHOP stock a huge percentage of the necessary parts. A list of factory-approved, independent manufacturing companies – most of which are based in Germany – will build any parts which might potentially be out of stock. Again, the specs of the parts used by SLSHOP are exacting. Only factory-approved will do.

The W113’s automatic boxes utilised fluid coupling, and not torque converter technology. The main difference is the latter makes use of a stator, placed between the impellor and the turbine, helping to multiply the torque and providing more efficient open road cruising. The tolerances and precision of Mercedes’ fluid coupling design, however, even back in the ‘60s, made for a super-smooth gearbox. At the time, it was unparalleled in terms of refinement and reliability. With SLSHOP focusing heavily (but not entirely) on the SLs in the Mercedes Benz range, Paul and the team in the workshop are best placed, and best qualified, to help keep these gems in perfect working order.

The Pagoda came standard with either a 4-speed manual or 4-speed auto, with a rarely optioned 5-speed manual ZF box on special order. One such unicorn was recently sourced and sold through the business. To add depth to today’s choices, SLSHOP now proudly offers a 6-speed manual conversion. The word ‘conversion’ is, in fact, a misleading description. What SLSHOP will do, is replace your existing box with a bespoke Getrag 6-speed unit. This gearbox can be fitted to either your Pagoda or your R107 SL.

Another pain point Paul and the technical team at SLSHOP deal with is being sent the gearbox removed from the vehicle. “Ideally, we want the gearbox while it’s still in the car,” he explains. “There are often issues with fitment and with the external control element. For example: poorly adjusted cables or modulating pressure or vacuum faults which are obviously only evident if the car is still in one piece.”

The R107s, built from 1971 – 1989 saw the introduction of the famed 722 series of automatic boxes. While the European spec list offered a 5-speed manual, the US only offered the auto. Unsurprisingly, irrespective of which side of the pond one studies, it’s the self-shifter that proved the most popular.

“We see some oil starvation issues and basic seal failure – all to be expected with age. A common modification is fitting a nylon bush (to replace an alloy one) in the B2 piston. Wear and tear of the alloy bush will damage the piston. The nylon unit is a fantastic fix, but if the piston is scored, that needs replacing too,” explains Paul. Like many classic car technical experts, Paul encourages people to drive their cars. If the car stands for prolonged periods of time, the paper seals and gaskets will become misshaped and result in pressure issues in the transmission.

- Azurite Blue SL500 for sale at SLSHOP

So good was the design of the 722 gearboxes, that the R129 SLs featured the 722 in modified form, beginning with the designation 722.4. Built from 1989 – 2001, the R129 SL was widely regarded as an engineering masterpiece with a plethora of automotive firsts. A 5-speed manual was available for the 6-cylinder models, but the V8s and V12s all had the automatic fitted. Even as the engines, the electronics, the materials, and the exterior and interior design were all making huge strides forward with the R129, the 722 gearboxes effortlessly kept pace. As the range progressed, so the upgrades to the box rolled on. 722.4 – a 4-speed. 722.5 – a 5-speed.

722.6 was the first major step forward for the unit with the introduction of electronics. Gone was the all-mechanical, analogue system of check-ball and spool valves, and control cables. A digital brain, throwing ones and zeros hither and thither, now replaced vacuum pressures and magnetically actuated solenoids that was fitted in the 722.5.

On the older units, a control cable, not unlike an accelerator cable, joins the throttle – on the carburettor or fuel injection system – to the gearbox’s valve chest. It acts as a position sensor, allowing the gearbox to ‘understand’ what the throttle position is and therefore the engine load. An override system is also fitted – a switch beneath the accelerator pedal that is connected to a solenoid in the valve chest. When you mash the throttle to the floor at lower speeds, the switch tells the solenoid to ‘kickdown’ to first gear. At higher road speeds – usually above 50mph – that kickdown system is bypassed and the valve chest, when asked for more performance, will select the next appropriate gear. 722.6 replaced all of this with circuit boards and electrically controlled solenoids. Paul suggests that kickdown is used sparingly to avoid wearing out the transmission.

In quizzing Paul about the any teething problems initially associated with the digi-brain, or any which have since reared a head, Paul says, “Electronically, you might see RPM sensor failure. Leaking electrical plugs are also common issues. The former will cause the car to go into limp mode, it won’t change beyond 2nd gear. Turning the ignition off and on again will reset this but the problem will resurface.” It goes without saying that any of these sorts of issues are easily dealt with by Paul and the team at SLSHOP.

In closing Paul proudly says, “I’m pedantic. I’m a stickler for doing the job right. And I’ve been doing this long enough to know when that gearbox is working the way it did the day it left the showroom, and when it isn’t. I’m also proud to say that we have an apprenticeship programme here at SLSHOP. Young Matthew is learning fast and quickly becoming a highly skilled technician in his own right. As it was done for me, I’m now passing on what I know.”

READ ABOUT OUR MANUAL CONVERSIONS

SLSHOP don’t restore, repair and sell SLs so that they can sit in a garage. They actively encourage the owners of these magnificent vehicles to drive them. The gearbox – one that is working as the designers intended it to – is an indispensable part of the driving experience. It is for this reason that SLSHOP is investing in these significant resources.

Paul also insists that SL owners understand that gearboxes, just like engines, need servicing. On the Pagoda, every 30 000 miles is your number. On the 722 series (R107 and R129), you’re looking at booking the car in every 36 000 miles. On the very latest Mercedes-Benz gearboxes (the 722.7 onwards), the service intervals are 72,000 miles.

SLSHOP is passionate about keeping these beautiful cars on the road for as long as possible. Sustainability, in the most contemporary understanding of the term, is a cornerstone of their operation. With technicians like Paul fixing rather than replacing, there’s far less ‘junk’ being sent to landfill. SLSHOP will warranty its gearbox rebuilds for 12 months. Follow Paul’s advice on the service intervals, and you’ll almost certainly never need to worry about the warranty.

If you’d like Paul and his team to get your gears shifting better than new, then why not book your Mercedes in today for a health check and honest chat about your options and our services.

SLSHOP Workshops

Share With Your Fellow Enthusiasts

More from Journal

CARE

THE ULTIMATE CERTIFIED SERVICING INVESTMENT PLAN

Your ownership journey matters to us, which is why we have created a simple certified servicing investment plan, tailored to your individual needs and aspirations.

Start investing today and our dedicated CARE team will work with you to increase the value and enjoyment you receive from your vehicle.

STAY IN TUNE WITH SLSHOP MOMENTS

As part of SLSHOP’s community of enthusiasts, you’ll be the first to hear about events and tours, key product offers, exciting stories from owners around the world and of course… our latest additions to the showroom. So, be the first to know and you might just sneak a car on your driveway or take your car’s condition to new heights with our exclusive replacement parts.

Or, visit SLSHOP Journal