Britain’s leading technical team gives us a rundown on common problems with 1980s and 1990s Mercedes-Benz gearboxes.

Better than a barn-find, the future classic, if you buy the right one, doesn’t need heaps of money thrown at it before its value is re-established. All it needs is maintenance, and all you need is patience. Better still, the fact that they’re only potentially a decade or two old means they’re often usable on a day-to-day basis. They’re comfortable, can easily cruise at highway speeds, and are almost certainly more reliable than a fifty-year-old car.

Mercedes-Benzes are a familiar blip on the radars of collectors and investors. For a good reason: The combination of style, engineering excellence and exclusivity often place them at the pinnacle of their contemporary best-in-class lists. And if a car was brilliant, sought-after and exclusive when it was new, chances are it will be desirable and valuable when it’s older.

As 50s and 60s Mercedes’ price tags draw ever-wider gawps from the jawlines of classic car buffs, eyes inadvertently laser-in on examples which both have room to mature financially and the ‘promise’ of consistent value escalation. And if that car is also practical to own and has a solid network of technical partners to help keep it in tip-top shape, then the boxes have all been ticked. The SL Shop are one such retail and technical partner for either the private buyer or the trade.

While all Mercedes-Benzes can be considered some of the most reliable cars on the road, they do need maintenance, and, as with all things mechanical, stuff does break. The SL Shop’s highly qualified and experienced technical team are among the UK’s most knowledgeable.

In this article, therefore, we’re going to drill down on a couple of SLs, which are, from a financial point of view, still relatively accessible and, from a practicality aspect, usable and maintainable. A veritable status symbol from the 70s and 80s, the R107; and the R129, that began production in 1989 and remained on the showroom floor till 2001.

But what are the symptoms of a faulty gearbox? We’ve asked the SLSHOP’s lead gearbox technician, Paul Smith, to talk to us through some of the common issues one might expect and what can be done to prevent or rectify them.

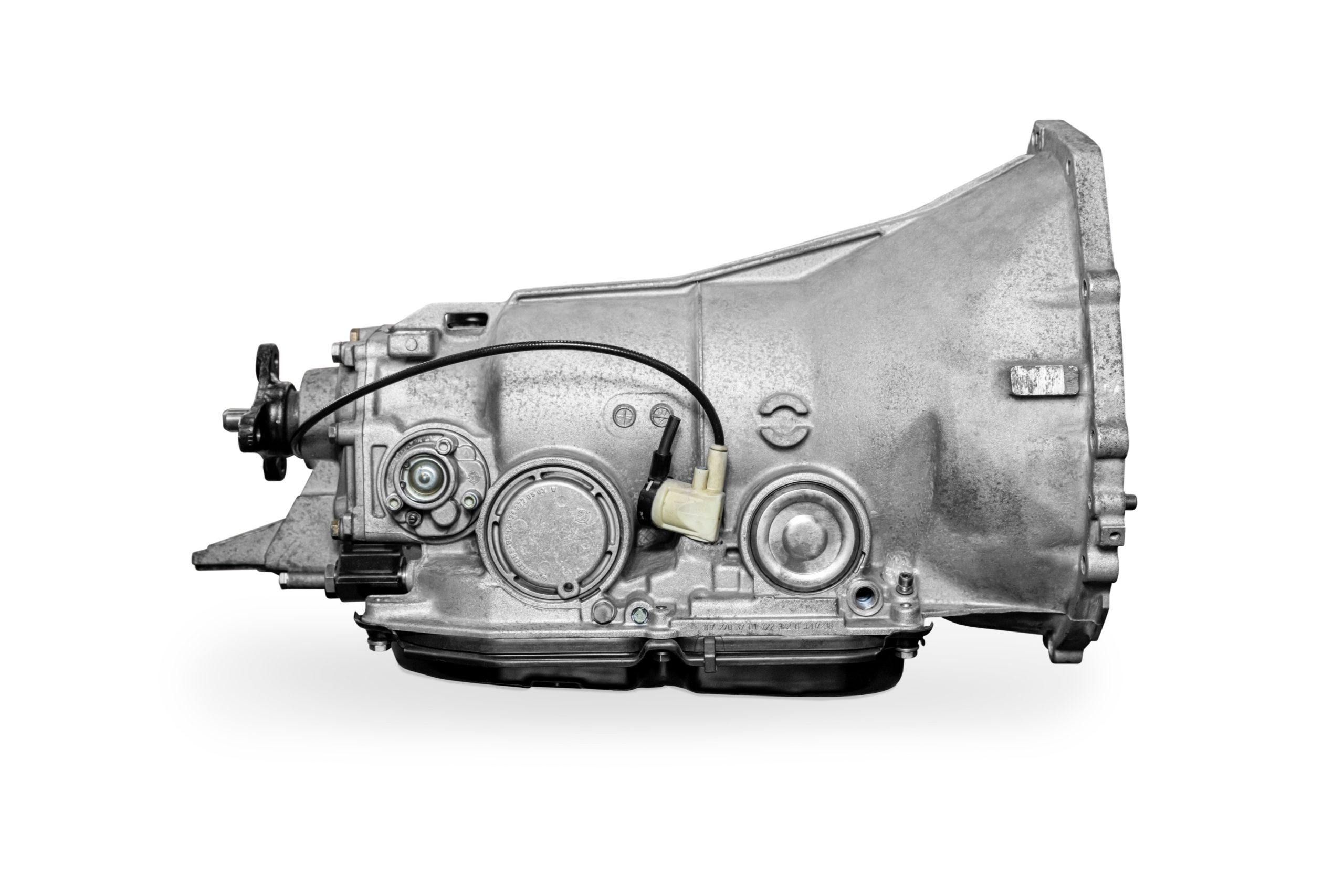

Introduced into the SL range with the 1971 R107, with model numbers 722.0, 722.1 and 722,3, the 722 gearboxes were so advanced and solid that its successor, R129, used the same (updated) unit. The R129 was widely regarded as an automotive tour de force with a long list of engineering firsts.

The 722 range, however, debuted for the brand several years earlier, with various 1960s saloons being fitted with this unit. So versatile and reliable were those early transmissions that a unique, improved version (722.003) was developed in 1975 and coupled to the 6.8-litre engine installed in the 450 SEL 6.9 model. This unit’s durability still baffles transmission repair experts to this day.

The 722.3/4, used between 1980 – 1995, may present the following issues:

1. Incorrect adjustment of control cable.

An incorrectly adjusted control cable can significantly affect the smooth operation of the transmission. Common symptoms are harsh gear upshifts, delayed upshifts, 4th being reached too quickly, and no partial downshifts. Adjustment of the control cable usually rectifies these problems.

2. Poor Modulating Pressure

An incorrectly set modulating pressure valve can result in both harsh upshifts and slipping upshifts. A check of the modulating pressure via a pressure gauge is required.

3. Split or disconnected vacuum to the modulator pressure valve.

Harsh upshifts in all gears will be present when driving. A test of the transmission vacuum system will be required.

4. Loss of drive after forty miles of driving or transmission has reached full operating temperature.

This issue is generally found in low-mileage vehicles left standing or in storage. To remedy this, a complete refurbishment of the transmission is required. Corrugated gaskets and failed or sticking control valves mean a thorough service.

The 722.5 was the brand’s first electronic, 5-speed transmission.

“We have only seen one of these in two years come to us with issues. This was the first electronic transmission offered by MB and is basically a 722.4 with a clutch pack put on the back and a solenoid controlled via electrical signals from the ECU. Rather than issues, it is worth highlighting how robust this gearbox is. What makes it unique is that faults can be diagnosed with a ‘Blink Code Diagnostics’ kit, so faults are generally easier to identify,” says Smith.

There are reports, however, of the failure of the 5th gear in this transmission. Transmission fluid shortages or pressure issues are usually the cause. This problem can be diagnosed while driving the car in the following way: When the transmission shifts from 4th to 5th, the driver will notice an unusual increase in the RPMs. If an expert does not promptly address the problem, the 5th gear will stop working altogether, as friction discs will get burnt.

To compound this dilemma, debris from the burnt friction discs could contaminate the entire transmission and clog the filter. The pressure in the system will drop, increasing the overall wear. Eventually, the transmission will fail. To guard the 722.5 (and 722.6) against premature failures, if these issues are not dealt with quickly enough, replacing the planetary gear and the 5th gear friction disc package may be necessary. Therefore, the question, “How much does it cost to fix a Mercedes transmission,” could be significantly more affordable with some preventative maintenance.

Furthermore, “older” 722.5 transmissions could be sensitive to overheating. ATF leaks lead to oil starvation and the consequent damage of friction mechanisms.

A common issue with the 722.6 is the rpm sensor, which when faulty, the vehicle will be held in limp mode and not change above 2nd gear. Recycling the ignition (i.e. starting the car again) can temporarily rectify the fault, but once the rpm sensor has failed, the fault will return quickly. A short test via the vehicle’s diagnostics systems with a handheld tester will indicate an RPM sensor fault. To rectify, we replace the electric plate which contains the actual RPM sensor. To do this, removing the valve chest is necessary as the electric plate sits on top.

Over time, almost all high-mileage 722.6 transmissions will be affected by wear of the torque converter lock-up mechanism. Debris from friction linings of the lock-up clutch will contaminate the ATF. The transmission fluid, mixed with the frictional dust, then leads to wear of the solenoids and potentially the valve body and friction mechanisms of the transmission. These problems will lead to a slow death for the transmission.

Paul Smith isn’t promising that scheduled maintenance will guarantee an ongoing and faultless gearbox experience. But a few points have, over time, been proven to be all but inevitable: a lack of maintenance dramatically increases the chances of almost all of these problems, and allowing an organisation like SLSHOP to care for all mechanical components of your car expertly, is your best chance of trouble-free motoring and value retention.

Share With Your Fellow Enthusiasts

Britain’s leading technical team gives us a rundown on common problems with 1980s and 1990s Mercedes-Benz gearboxes.

Better than a barn-find, the future classic, if you buy the right one, doesn’t need heaps of money thrown at it before its value is re-established. All it needs is maintenance, and all you need is patience. Better still, the fact that they’re only potentially a decade or two old means they’re often usable on a day-to-day basis. They’re comfortable, can easily cruise at highway speeds, and are almost certainly more reliable than a fifty-year-old car.

Mercedes-Benzes are a familiar blip on the radars of collectors and investors. For a good reason: The combination of style, engineering excellence and exclusivity often place them at the pinnacle of their contemporary best-in-class lists. And if a car was brilliant, sought-after and exclusive when it was new, chances are it will be desirable and valuable when it’s older.

As 50s and 60s Mercedes’ price tags draw ever-wider gawps from the jawlines of classic car buffs, eyes inadvertently laser-in on examples which both have room to mature financially and the ‘promise’ of consistent value escalation. And if that car is also practical to own and has a solid network of technical partners to help keep it in tip-top shape, then the boxes have all been ticked. The SL Shop are one such retail and technical partner for either the private buyer or the trade.

While all Mercedes-Benzes can be considered some of the most reliable cars on the road, they do need maintenance, and, as with all things mechanical, stuff does break. The SL Shop’s highly qualified and experienced technical team are among the UK’s most knowledgeable.

In this article, therefore, we’re going to drill down on a couple of SLs, which are, from a financial point of view, still relatively accessible and, from a practicality aspect, usable and maintainable. A veritable status symbol from the 70s and 80s, the R107; and the R129, that began production in 1989 and remained on the showroom floor till 2001.

But what are the symptoms of a faulty gearbox? We’ve asked the SLSHOP’s lead gearbox technician, Paul Smith, to talk to us through some of the common issues one might expect and what can be done to prevent or rectify them.

Introduced into the SL range with the 1971 R107, with model numbers 722.0, 722.1 and 722,3, the 722 gearboxes were so advanced and solid that its successor, R129, used the same (updated) unit. The R129 was widely regarded as an automotive tour de force with a long list of engineering firsts.

The 722 range, however, debuted for the brand several years earlier, with various 1960s saloons being fitted with this unit. So versatile and reliable were those early transmissions that a unique, improved version (722.003) was developed in 1975 and coupled to the 6.8-litre engine installed in the 450 SEL 6.9 model. This unit’s durability still baffles transmission repair experts to this day.

The 722.3/4, used between 1980 – 1995, may present the following issues:

1. Incorrect adjustment of control cable.

An incorrectly adjusted control cable can significantly affect the smooth operation of the transmission. Common symptoms are harsh gear upshifts, delayed upshifts, 4th being reached too quickly, and no partial downshifts. Adjustment of the control cable usually rectifies these problems.

2. Poor Modulating Pressure

An incorrectly set modulating pressure valve can result in both harsh upshifts and slipping upshifts. A check of the modulating pressure via a pressure gauge is required.

3. Split or disconnected vacuum to the modulator pressure valve.

Harsh upshifts in all gears will be present when driving. A test of the transmission vacuum system will be required.

4. Loss of drive after forty miles of driving or transmission has reached full operating temperature.

This issue is generally found in low-mileage vehicles left standing or in storage. To remedy this, a complete refurbishment of the transmission is required. Corrugated gaskets and failed or sticking control valves mean a thorough service.

The 722.5 was the brand’s first electronic, 5-speed transmission.

“We have only seen one of these in two years come to us with issues. This was the first electronic transmission offered by MB and is basically a 722.4 with a clutch pack put on the back and a solenoid controlled via electrical signals from the ECU. Rather than issues, it is worth highlighting how robust this gearbox is. What makes it unique is that faults can be diagnosed with a ‘Blink Code Diagnostics’ kit, so faults are generally easier to identify,” says Smith.

There are reports, however, of the failure of the 5th gear in this transmission. Transmission fluid shortages or pressure issues are usually the cause. This problem can be diagnosed while driving the car in the following way: When the transmission shifts from 4th to 5th, the driver will notice an unusual increase in the RPMs. If an expert does not promptly address the problem, the 5th gear will stop working altogether, as friction discs will get burnt.

To compound this dilemma, debris from the burnt friction discs could contaminate the entire transmission and clog the filter. The pressure in the system will drop, increasing the overall wear. Eventually, the transmission will fail. To guard the 722.5 (and 722.6) against premature failures, if these issues are not dealt with quickly enough, replacing the planetary gear and the 5th gear friction disc package may be necessary. Therefore, the question, “How much does it cost to fix a Mercedes transmission,” could be significantly more affordable with some preventative maintenance.

Furthermore, “older” 722.5 transmissions could be sensitive to overheating. ATF leaks lead to oil starvation and the consequent damage of friction mechanisms.

A common issue with the 722.6 is the rpm sensor, which when faulty, the vehicle will be held in limp mode and not change above 2nd gear. Recycling the ignition (i.e. starting the car again) can temporarily rectify the fault, but once the rpm sensor has failed, the fault will return quickly. A short test via the vehicle’s diagnostics systems with a handheld tester will indicate an RPM sensor fault. To rectify, we replace the electric plate which contains the actual RPM sensor. To do this, removing the valve chest is necessary as the electric plate sits on top.

Over time, almost all high-mileage 722.6 transmissions will be affected by wear of the torque converter lock-up mechanism. Debris from friction linings of the lock-up clutch will contaminate the ATF. The transmission fluid, mixed with the frictional dust, then leads to wear of the solenoids and potentially the valve body and friction mechanisms of the transmission. These problems will lead to a slow death for the transmission.

Paul Smith isn’t promising that scheduled maintenance will guarantee an ongoing and faultless gearbox experience. But a few points have, over time, been proven to be all but inevitable: a lack of maintenance dramatically increases the chances of almost all of these problems, and allowing an organisation like SLSHOP to care for all mechanical components of your car expertly, is your best chance of trouble-free motoring and value retention.

Share With Your Fellow Enthusiasts

More from Journal

CARE

THE ULTIMATE CERTIFIED SERVICING INVESTMENT PLAN

Your ownership journey matters to us, which is why we have created a simple certified servicing investment plan, tailored to your individual needs and aspirations.

Start investing today and our dedicated CARE team will work with you to increase the value and enjoyment you receive from your vehicle.

STAY IN TUNE WITH SLSHOP MOMENTS

As part of SLSHOP’s community of enthusiasts, you’ll be the first to hear about events and tours, key product offers, exciting stories from owners around the world and of course… our latest additions to the showroom. So, be the first to know and you might just sneak a car on your driveway or take your car’s condition to new heights with our exclusive replacement parts.

Or, visit SLSHOP Journal