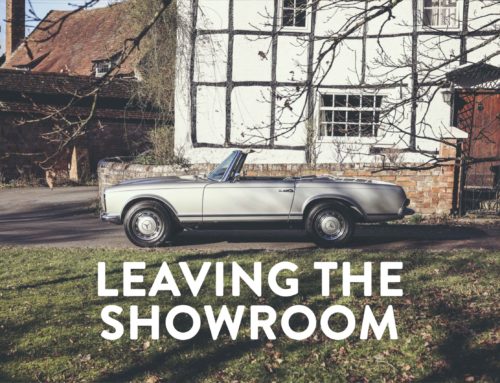

This 190 SL W121 arrived at SLSHOP following a six-figure bottom-up restoration – work that was carried out externally at an extremely reputable organisation. An outfit that SLSHOP regularly works in tandem with, exchanging knowledge and guidance with one another. Without this level of cooperation, these vehicles simply wouldn’t exist, and we would lose an extremely important part of automotive history.

Part of this restoration involved a complete engine rebuild, with each serviceable item being removed, replaced, or refurbished. The customer delivered the car to us reporting that the car simply wasn’t performing to the standards of a virtually new engine. While the W121 is notorious for lacking the brute of its 300 SL/R cousins, there is still plenty to be enjoyed from these well-constructed 4-cylinder engines.

Enter Dan, our lead Heritage technician. Starting with a series of road tests, Dan acknowledged the lack of performance out on the road before returning to the workshops to discover a severe oil leak. This was traced to the rear crank seal before the engine was once again removed. Dan took his time to strip the engine down, before completely removing the crank – it was here that problems started to emerge. The block was far from perfect.

An inspection of the shell bearings found that they were neither smooth nor sitting correctly between the crank and conrod. Shell bearings are lubricated by oil from the oil pump, forming a pressure film that will prevent any metal contact between the crank and conrod. Dan has hypothesised that when the crank was machined, it has caused a swarf in the oil, which has run through the crank, impacting the position of the shell bearings. These bearings will all be replaced.

Further along the strip down process, Dan was also unable to remove the conrods without welding them tight. This was due to the nut spinning. All these occurrences were signs that the engine hadn’t received the full attention required. The conrod will be replaced, while the crank will also be sent off to be measured, polished and replaced if necessary.

With all the classic Mercedes restoration projects we dive into, there are surprises along the way. Until all mechanical and cosmetic parts have been inspected, you simply don’t know what you will find. This was certainly the case here, as the engine unit also had two leaking valves and two missing valve stem oil seals, as well as rotten water jackets as illustrated in the image below.

Water jackets are cavities that allow coolant to cool the cylinders. This prevents them from getting too hot, avoiding a premature ignition of air and fuel which would cause extreme stress on the engine. Coolant is circulated around the cylinders through these water jacket voids, generally passing from the bottom to the head. Poorly circulating coolant and as in this case, rotten jackets could be the cause of overheating and thus, lack of performance.

Luckily, the owner brought this 190 SL to SLSHOP almost immediately after it had been cosmetically and structurally restored, avoiding any further damage to the engine. Now Dan has worked his magic on the unit and returned it to the engine bay, the last final bolts can be fitted. We look forward to seeing the smiles per gallon revealed by the owner as they drive off into the distance.

If you’d like to discuss service or restoration work with SLSHOP, please contact [email protected]. SLSHOP are specialists with the capacity to carry out full restorations, as well as minor routine servicing and maintenance work. SLSHOP’s expertise spans Mercedes models from the fifties through to the 2000s.

Share With Your Fellow Enthusiasts

This 190 SL W121 arrived at SLSHOP following a six-figure bottom-up restoration – work that was carried out externally at an extremely reputable organisation. An outfit that SLSHOP regularly works in tandem with, exchanging knowledge and guidance with one another. Without this level of cooperation, these vehicles simply wouldn’t exist, and we would lose an extremely important part of automotive history.

Part of this restoration involved a complete engine rebuild, with each serviceable item being removed, replaced, or refurbished. The customer delivered the car to us reporting that the car simply wasn’t performing to the standards of a virtually new engine. While the W121 is notorious for lacking the brute of its 300 SL/R cousins, there is still plenty to be enjoyed from these well-constructed 4-cylinder engines.

Enter Dan, our lead Heritage technician. Starting with a series of road tests, Dan acknowledged the lack of performance out on the road before returning to the workshops to discover a severe oil leak. This was traced to the rear crank seal before the engine was once again removed. Dan took his time to strip the engine down, before completely removing the crank – it was here that problems started to emerge. The block was far from perfect.

An inspection of the shell bearings found that they were neither smooth nor sitting correctly between the crank and conrod. Shell bearings are lubricated by oil from the oil pump, forming a pressure film that will prevent any metal contact between the crank and conrod. Dan has hypothesised that when the crank was machined, it has caused a swarf in the oil, which has run through the crank, impacting the position of the shell bearings. These bearings will all be replaced.

Further along the strip down process, Dan was also unable to remove the conrods without welding them tight. This was due to the nut spinning. All these occurrences were signs that the engine hadn’t received the full attention required. The conrod will be replaced, while the crank will also be sent off to be measured, polished and replaced if necessary.

With all the classic Mercedes restoration projects we dive into, there are surprises along the way. Until all mechanical and cosmetic parts have been inspected, you simply don’t know what you will find. This was certainly the case here, as the engine unit also had two leaking valves and two missing valve stem oil seals, as well as rotten water jackets as illustrated in the image below.

Water jackets are cavities that allow coolant to cool the cylinders. This prevents them from getting too hot, avoiding a premature ignition of air and fuel which would cause extreme stress on the engine. Coolant is circulated around the cylinders through these water jacket voids, generally passing from the bottom to the head. Poorly circulating coolant and as in this case, rotten jackets could be the cause of overheating and thus, lack of performance.

Luckily, the owner brought this 190 SL to SLSHOP almost immediately after it had been cosmetically and structurally restored, avoiding any further damage to the engine. Now Dan has worked his magic on the unit and returned it to the engine bay, the last final bolts can be fitted. We look forward to seeing the smiles per gallon revealed by the owner as they drive off into the distance.

If you’d like to discuss service or restoration work with SLSHOP, please contact [email protected]. SLSHOP are specialists with the capacity to carry out full restorations, as well as minor routine servicing and maintenance work. SLSHOP’s expertise spans Mercedes models from the fifties through to the 2000s.

Share With Your Fellow Enthusiasts

More from Journal

CARE

THE ULTIMATE CERTIFIED SERVICING INVESTMENT PLAN

Your ownership journey matters to us, which is why we have created a simple certified servicing investment plan, tailored to your individual needs and aspirations.

Start investing today and our dedicated CARE team will work with you to increase the value and enjoyment you receive from your vehicle.

STAY IN TUNE WITH SLSHOP MOMENTS

As part of SLSHOP’s community of enthusiasts, you’ll be the first to hear about events and tours, key product offers, exciting stories from owners around the world and of course… our latest additions to the showroom. So, be the first to know and you might just sneak a car on your driveway or take your car’s condition to new heights with our exclusive replacement parts.

Or, visit SLSHOP Journal